Have you ever found yourself puzzled by the terms BOPP and OPP when sourcing industrial tapes? You’re not alone. The jargon can be confusing, especially when you’re looking for the best material for your specific needs.

BOPP and OPP are both types of polypropylene films used in tape manufacturing. While they share similarities, they also have distinct properties that make them suitable for different applications.

So, why should you care about these materials? Well, knowing the difference can save you time, money, and a lot of headaches. Let’s dive in.

What is BOPP, Anyway?

BOPP stands for Biaxially Oriented Polypropylene. It’s a film stretched in both machine and cross directions, providing superior strength and clarity. This material is commonly used in packaging, labeling, and, of course, tape manufacturing.

And What About OPP?

On the other hand, OPP or Oriented Polypropylene is stretched in only one direction. It’s generally less rigid and offers less clarity than BOPP but is still a viable option for many applications.

Why Choose BOPP Over OPP?

So, when should you opt for BOPP? Due to its biaxial orientation, BOPP tapes are more durable and resistant to abrasion, making them ideal for heavy-duty packaging and industrial applications.

When is OPP the Better Choice?

OPP tapes are generally more cost-effective and are suitable for light to medium-duty applications. They are often used in stationery and general-purpose taping.

How Do They Perform in Various Conditions?

BOPP films are known for their excellent moisture resistance, making them ideal for humid conditions. OPP, while also moisture-resistant, may not perform as well in extreme conditions.

What About Customization and Printing?

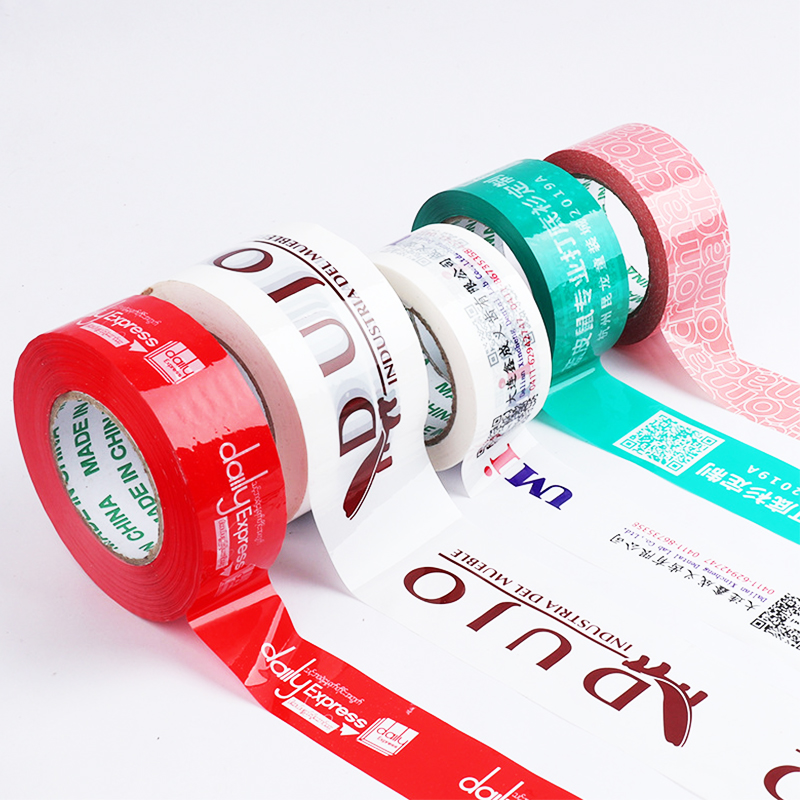

Both materials are printable, but BOPP offers superior print quality. If your project requires high-definition printing, BOPP is your go-to material.

Environmental Impact: Which is Greener?

Both BOPP and OPP are recyclable materials. However, BOPP is often considered more environmentally friendly due to its lower density, which means less material is needed for the same application.

Conclusion

Understanding the differences between BOPP and OPP can significantly impact your project’s success. BOPP offers higher durability and clarity, making it ideal for heavy-duty applications and high-quality printing. On the other hand, OPP is more cost-effective and suitable for lighter tasks. Both materials have their merits, and your choice should depend on your specific needs.

That’s it for today’s lesson in tapeology. May your tapes always stick and your choices be ever clear!